PET FOOD PROCESSING

PET FOOD FOR CATS AND DOGS

PETFOOD LINE

Steam tunnel processing; a reliable and efficient technology with great flexibility in shape and color!

PROCESS

A good quality end product starts with the right recipe and preparation of the ingredients. A good meat emulsion is an essential part of the production process.

This meat emulsion is transported from the emulsifier to the Selo hopper. After this, the continuous process of rope forming, cooking, cooling and cutting the ropes into chunks begins. The hopper has a buffer function, which guarantees a constant flow to the extruder.

From the hopper the meat emulsion is pumped to the extruder. On the way, by means of in-line dosing the required color and/or other ingredients can be added to create a greater diversity of end product in a flexible manner. Optionally, a metal detection system can be added in the pipeline, as an extra means of guaranteeing the quality and safety of the product and process even better.

The extruder forms the meat emulsion into regular (or if required irregular) shapes of ropes which are formed on the conveyor belt of the steam tunnel. The openings of the form lists / dies in the extruder can optionally be provided with various dimensions of shapes, these ensure the final shape and size of the chunk. The form lists / dies can be changed quickly and easily, which guarantees a short changeover time

After forming and placing the ropes on the conveyor belt, they go through the steam tunnel. The meat emulsion is cooked during this process. The settings of the entire line, such as speed and temperature, are completely recipe-controlled, in order to guarantee the highest possible product quality and production efficiency.

OCELOT SERIES

Small, fast and no frills. The Ocelot series is the smallest of the Selo series. The ocelot is a very compact all-in-one line which includes all the necessary features.

Equipped with a spreader system and a Teflon belt the Selo ocelot series ensures a no frill, smooth consistent and efficient production process with a capacity up to 300 kg of meat chunks per hour.

CHEETAH SERIES

Dynamic and majestic, The Selo Cheetah series are designed for high flexibility in processing options in a medium capacity range. The line is based on a 400mm wide belt system.

Both Teflon and stainless steel belts as well as spreader and extrusion systems are available in the Cheetah range. A color injection is optional for this multi-talent with production capacities up to 750 kg of meat chunks per hour.

SERVAL SERIES

Named after an elegant, powerful and strong creature the Selo Serval series will serve your needs.

This series is designed for medium to high capacities and can include full options with multiple extruders or spreaders which will enable you to produce up to 4 different colors and multiple shapes of chunks at one time. A long lasting durable continuous stainless steel belt is the standard while on selected steamtunnels Teflon belts are optionally available.

The production capacity of the Serval series is up to 2.500 kg of meat chunks per hour.

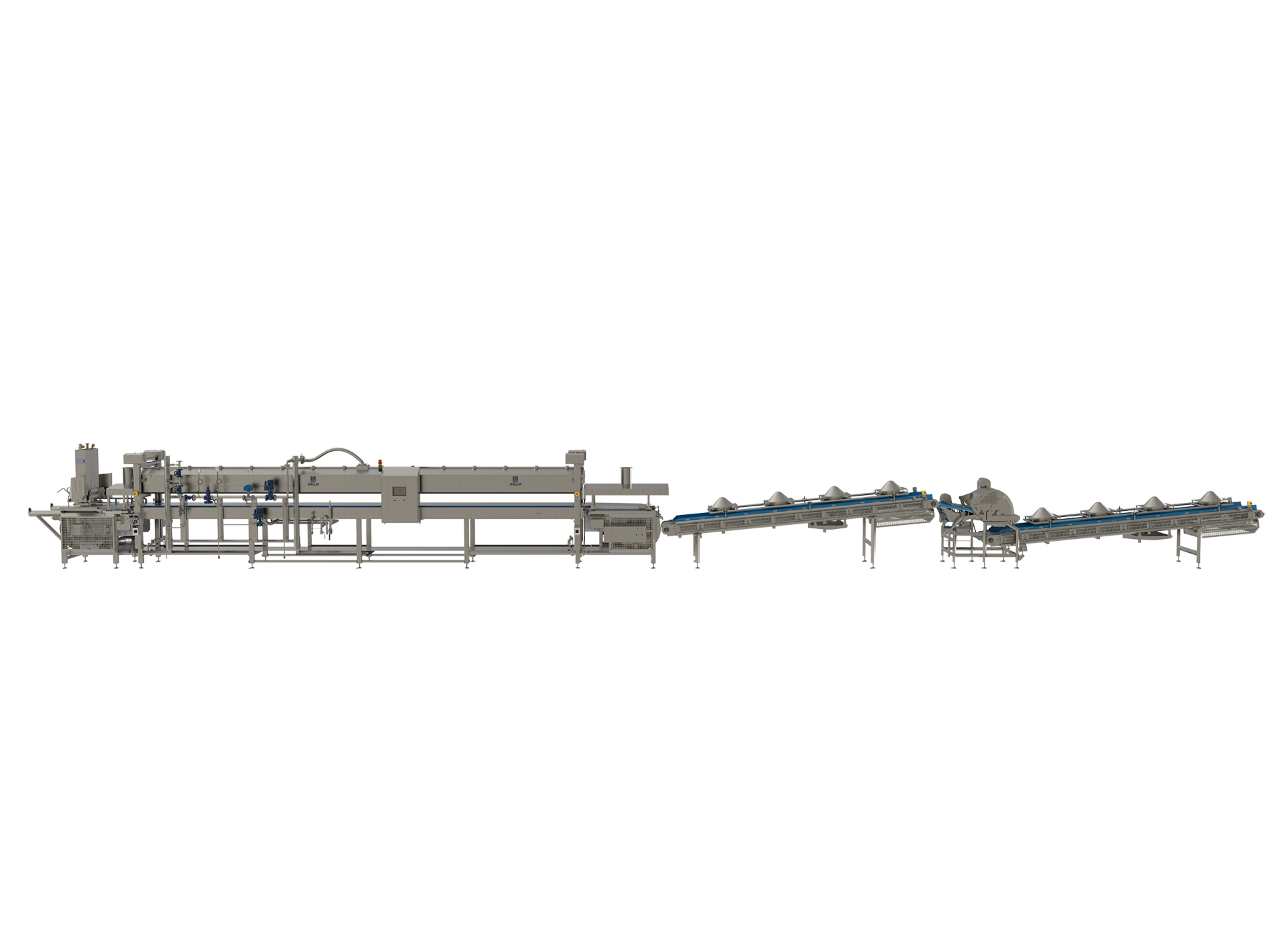

AMUR SERIES

The most powerful and largest beast of our the Selo series is the Amur which is not to be tamed in smaller spaces.

The Selo Amur series is designed and built for heavy duty and high capacity production of wet pet food, whilst keeping all the flexibility and possibilities to produce short batch runs. Just like the Serval series all options are available on these magnificent lines. Chunk processing capacities up to 5.000 kg of meat chunks per hour are no issue for the Amur series.